Date:2014-06-24

1830/1840 Series / 정밀급 수위센서

Feature

측정범위: 0.75 to 600 mH2O

• 정확도: ±0.06%FS(BSL)

• 1730: Vented polyurethane cable

• 1740: Vented Hytrel® 6108 cable

신제품 UNIK 5000 pressure sensor의 platform은 구성품간의 모듈을 기반으로 Druck사의 실리콘 센싱 소자 기술, 아날로그 전기회로 기술이 결합된 제품입니다. 이러한 modular design 생산방식은 기존의 제품 보다 납기가 짧아지게 되었습니다.높은 정확도와 당신이 요청하는 Spec은 이러한 기본 구성부품들로 부터 소비자 맞춤형 압력센서가 가능토록합니다.일반적인 application은 가스&오일, 자동차 분야 항공분야 뿐만아니라 현장의 공압/유압 설비의 테스트 설비 적합하도록 설계되었습니다.

Quairty Piezo-Resistive Sensor

Stainless steel module Analogue 전자 기술

(1) 빠른 turn on

(2) 응답속도: 5kHz

(3) 낮은 noise

(4)정확도: 0.04%

(5)안정도: 0.05%

Short Lead Times

상호 결합이 가능한 모듈 부품의 stock 보유 소비자 요구에 맞게 구성품 조립 생산

Price Advantage

소량주문 가능

기본 구성품으로부터 재조된 다양한 변화

Flexible Platform

압력 연결 fitting

압력 범위

출력 신호 타입

출력 단자 wireing 타입

온도 보상 범위

원하는 정확도

Measurement

Gauge ranges

Any zero based range between 70 mbar and 70 bar (1 to 1,000 psi)

(values inpsi are approximate)

Sealed Gauge Ranges

Any zero based range between 10 and 700 bar (145 to 10,000 psi)

Absolute Ranges

Any zero based range between 350 mbar and 700 bar (5 to 10,000 psi)

Operating Pressure Range

Differential Ranges

Wet/Dry

Uni-directional or bi-directional 70 mbar to 35 bar (1 to 500 psi)

Wet/Wet

Uni-directional or bi-directional 350 mbar to 35 bar (5 to 500 psi)

Line pressure: 70 bar max (1000 psi)Barometric Ranges

Barometric ranges are available with a minimum span of 350 mbar (5.1 psi)

Non Zero Based Ranges

Non zero based ranges are available. Contact

GE to discuss your requirementsOver Pressure

• 10 × FS for ranges up to 150 mbar (2 psi)

• 6 × FS for ranges up to 700 mbar (10 psi)

• 2 × FS for barometric ranges

• 4 × FS for all other ranges (up to 200 bar for ranges ≤70 bar and up to 1200 bar for ranges >70 bar) For differential versions the negative side must notexceed the positive side by more than:

• 6 × FS for ranges up to 150 mbar (2 psi)

• 4 × FS for ranges up to 700 mbar (10 psi)

• 2 × FS for all other ranges up to a maximum of 15 bar (200 psi)

Containment Pressure

Gauge, Sealed Gauge, Absolute and Differential (+ve port):

• 6 × FS for ranges up to 70 bar (1000 psi) (200 bar (2,900 psi) maximum)

• 6 × FS for ranges above 70 bar (1000 psi) (1200 bar (17,000 psi) maximum)

Differential (-ve port) must not exceed positive port by more than 4 × FS (15 bar (200 psi) maximum)

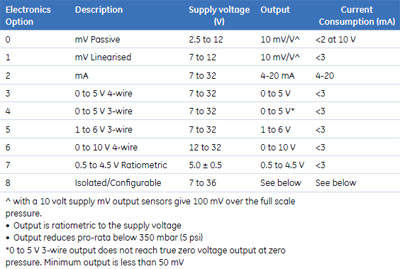

Supply and Outputs

Isolated/Configurable

(Option 8)

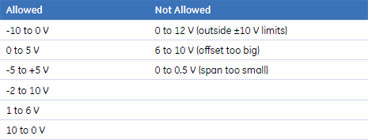

Any pressure signal output configurations will be available, subject to the following limitations:

• Minimum span: 2 V

• Maximum span: 20 V

• Output limits: ±10 V

• Maximum zero offset: ≤ span

Reverse output response to pressure is available.The output will continue to respond to 110% FS. i.e. if a 0 to 10 V output is specified, the output will continue to increase proportionally to applied pressure until at least 11 V. Current consumption is <20 mA @ 7 Vdc supply, reducing to <5 mA @ 32 Vdc supply. On startup <100 mA drawn for 10 ms typically.

Example

Power-Up Time

mV, Voltage and current versions: 10 ms

Isolated/configurable version: 500 ms

Shunt Calibration

Shunt Calibration provides customer accessible connections which, when shorted together, cause a shift in output of 80% FS in order to simulate applied pressure. It is fitted to the mV and Isolated/Configurable versions as standard. It is not available with a DIN electrical connector (Option 7).

Performance

Voltage, Current and mV Linearised

Combined effects of non-linearity, hysteresis and repeatability:Industrial: ±0.2% FS BSL

Improved: ±0.1% FS BSL

Premium: ±0.04% FS BSLAccuracy

mV Passive

≤ 70 bar

Industrial: ±0.2% FS BSL

Improved: ±0.1% FS BSL> 70 bar

Industrial: ±0.5% FS BSL

Improved: ±0.5% FS BSLZero Offset

and Span Setting

Voltage and Current Outputs

Adjustable Zero and Span Connector Versions

Adjustable electrical connector options allow access to potentiometers that give at least ±5% FS adjustment (see Electrical Connector section)Factory set to:

Industrial: ±0.5% FS

Improved: ±0.2% FS

Premium: ±0.2% FSLong Term Stability

Fixed Zero and Span

Connector Versions

All specifications: ±1% FS

mV Outputs

All specifications ±3 mV

Long Term Stability

±0.05% FS typical (±0.1% FS maximum) per year increasing pro-rata for pressure ranges below 350 mbar

Temperature Effects

Four compensated temperature ranges can be chosen.

Industrial Accuracy performance:

-10 to +50 °C (-14 to +122 °F): ±0.75% FS, Temperature error band (TEB)

-20 to +80 °C (-4 to 176 °F): ±1.5% FS TEB

-40 to +80 °C (-40 to 176 °F):: ±2.25% FS TEB

-40 to +125 °C (-40 to 257 °F): ±2.25% FS TEBImproved and Premium Accuracy performance:

-10 to +50 °C (-14 to +122 °F): ±0.5% FS TEB

-20 to +80 °C (-4 to 176 °F): ±1.0% FS TEB

-40 to +80 °C (-40 to 176 °F): ±1.5% FS TEB

-40 to +125 °C (-40 to 257 °F): ±1.5% FS TEBTemperature effects increase pro-rata for pressure ranges below 350 mbar (5 psi) and are doubled for barometric ranges.

Physical

Environmental Protection

• See Electrical Connector section

• Hyperbaric Pressure: 20 bar (300 psi) maximumOperating

Temperature Range

See Electrical Connector section

Pressure Media

Fluids compatible with Stainless Steel 316L and Hastelloy C276.

For the wet/dry differential version, the negative pressure port:

fluid compatible with stainless steel 316L, pyrex, silicone and structured adhesive.Pressure Connector

• G1/4 female*

• G1/4 male flat

• G1/4 male 60° internal cone

• G1/8 male 60° internal cone

• 1/4 NPT female*

• 1/4 NPT male

• 1/8 NPT male

• M20 x 1.5 male

• M14 x 1.5 60° internal cone

• M12 x 1 60° internal cone

• 7/16-20 UNF male

• G1/2 Male via welded Adaptor*

• 1/2 NPT Male via welded Adaptor*

• Depth Cone (G1/4 female)

Choose connectors marked * for pressure ranges over 70 bar.

Certification

• CE Marked

• RoHS

• EMC Standards

• BS EN 61000-6-2:2005 Susceptibility – Heavy Industrial (except mV versions)

• BS EN 61000-6-3:2007 Emissions – Light Industrial

• BS EN 61000-6-4:2007 Emissions – Heavy Industrial

• BS EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory Use – EMC requirementsBS EN 61000-6-1: 2007 Susceptibility – Light Industrial

견적 및 상담문의 | QnA

*개발문의등 질문을 남겨주시면

빠른 답변 드리겠습니다.

부산광역시 사상구 대동로 303 (감전동 벽산디지털밸리 621호) | 전화 : 051-329-7600 | 팩스: 051-329-7602

광주사업소 주소 : 광주광역시 북구 운용로 75 (트라움시티 414호) | 전화 : 062-511-7608 | 팩스: 062-511-7609

광주사업소 주소 : 광주광역시 북구 운용로 75 (트라움시티 414호) | 전화 : 062-511-7608 | 팩스: 062-511-7609

POWER by PICELL.BIZ